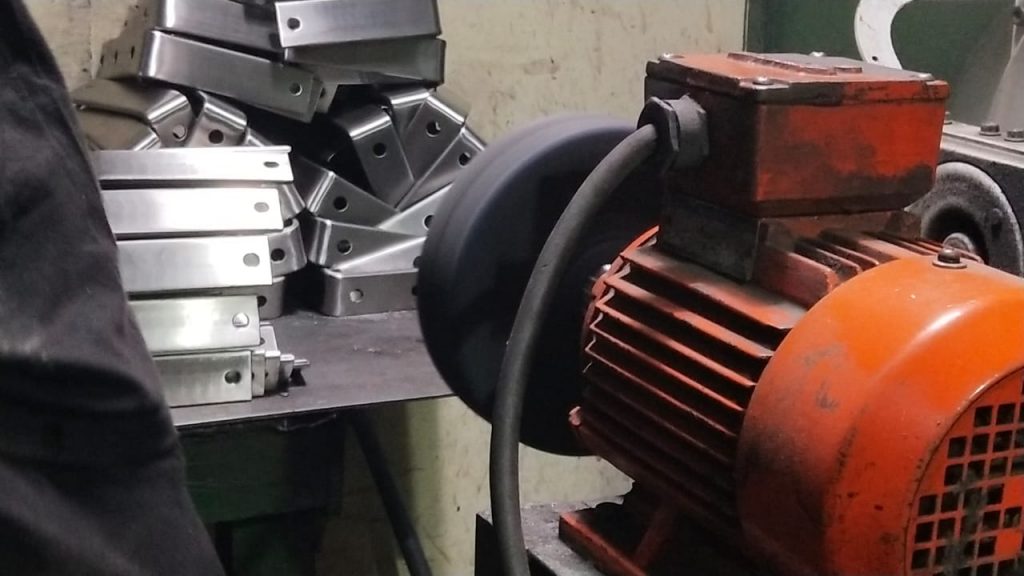

Our Machine

– Work area: 200 x 600

– KW: 2.8

– Automatic: (right – left, forward and back)

– Weight (kg): 700

– Power pressure: 60/63 KN

– Table length: 240×360 / 310×220 mm

– Table plate thickness: 50 / 30mm

– Motor: 1.1 / 0.75kw

– Overall Dimension: 920x650x1660

– Max.Swing Over Bed : 250mm

– Max. Swing Over Cross Slid : 152mm

– Distance Between Centres : 750mm

– Hole Through Spindle : 20mm

– SPindle Taper With Sleeve : MT3#

– Spindle Speed (6 Speeds) : 125 – 2000 Rpm

– Range of Longitudinal Feeds : 0.1-0.25mm

– Range of Metric Threads : 0.25-2.5mm

– Max.Tool Size : 14 x 14mm

– Taper in Tailstock Spindle : MT2#

This type of machine is commonly used for production and multipurpose work consists of a base frame and frame that supports horizontal arms. The workpiece is supported on a cross rail allowing the workpiece to be moved in the direction of crossing or vertically with the hand or power drive. On this machine the tool moves back and forth, while the workpiece performs a pulling motion. The maximum step length is up to 1000 mm, suitable for short and not too heavy objects.

– Kapasitas kerja 300 X 800 mm

– Slothing Head

– DRO 2 Aksis

– Akkurasi 0,05 mm

– Motor 3,5 Kw 200 V